Optimizing Logistic Terminals with AI

Idea Description

Optimizing Logistic Terminals with AI

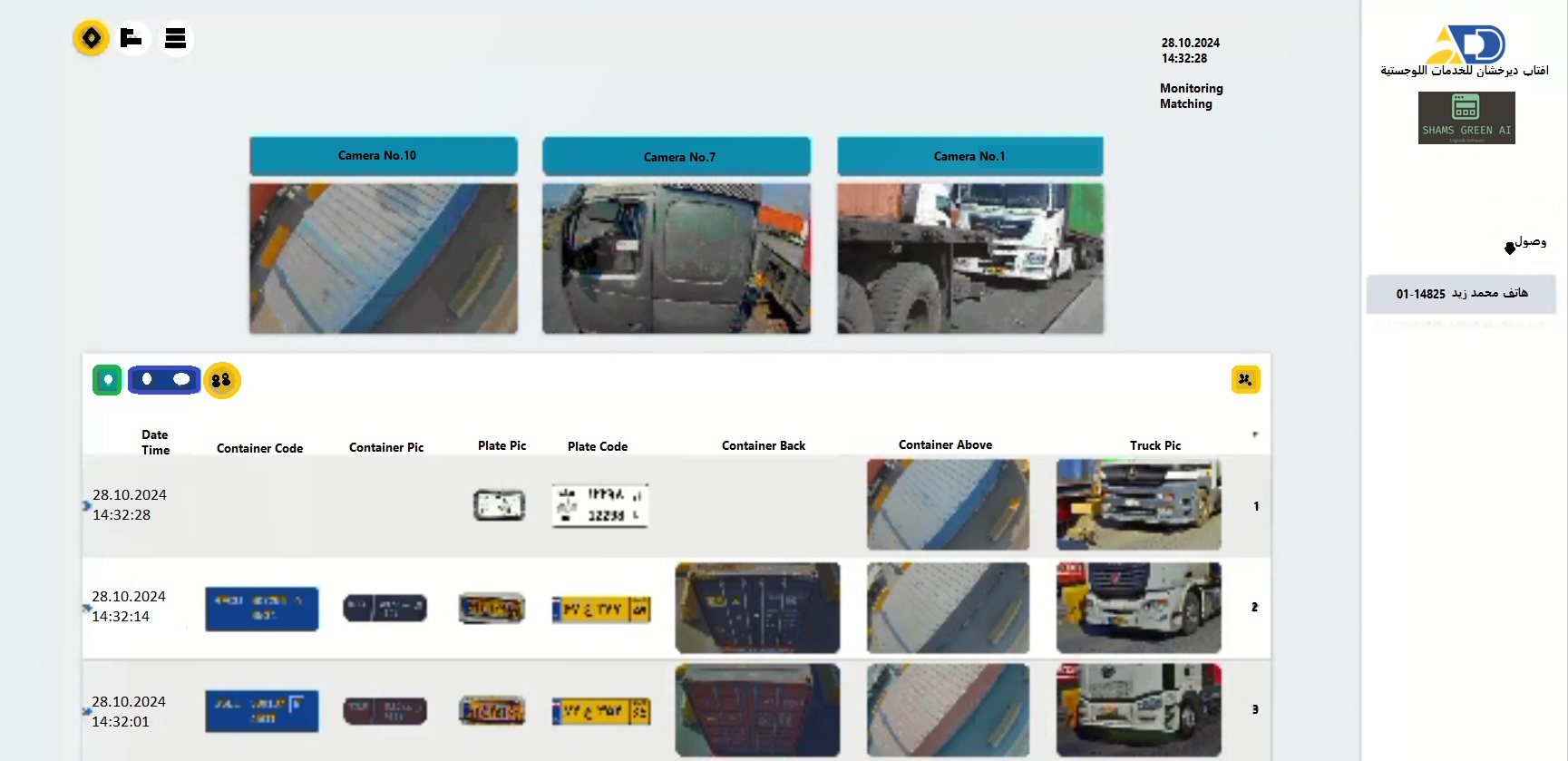

🗝️Plate code Inspection based AI

🗝️Container Volume based AI

🗝️Container ID based AI

🗝️load type based AI

🗝️Iso code

🗝️IMDG Label

🗝️IMO Class

🗝️Seal Presence

🗝️ Real-time Driver face Recognition based AI

🗝️ Real-time Container Damage Detection based AI

🗝️Real Time Location Recognition based AI for Trucks/Containers

🗝️Load Container security detection-based AI

⚡ All services are provided on one affordable platform Through API with ongoing support.

⚡No need for new ready-made infrastructure and capable of integrating with existing systems.

⚡Lower cost price

Challenges The Idea is Addressing

1-Inefficient Logistics Underutilized Capacity: Trucks often run with partial loads, wasting resources. Inefficient Routes: Suboptimal planning increases fuel consumption and delivery times. 2-High Carbon Emissions Significant Contributor: Freight transport accounts for 30% of logistics-related CO₂ emissions in Europe. Regulatory Pressure: Stricter EU decarbonization policies demand immediate solutions. 3-Lack of Real-Time Intelligence Outdated Systems: Many logistics systems are unable to dynamically adapt to changes such as traffic or weather. Data Silos: Fragmented data prevents holistic decision-making across supply chains. 4-Rising Costs Fuel Prices: Increasing fuel costs directly impact margins. Operational Inefficiencies: Manual processes and delayed decisions lead to financial losses. 5. Complex Stakeholder Needs Diverse Requirements: Coordinating shippers, carriers, and warehouses remains a logistical challenge. Limited Visibility: End-to-end tracking and monitoring of goods are often inadequate.

Benefits of Idea Implementation

1-Intelligent Load Optimization AI Algorithms: Maximize truck/container utilization by consolidating loads efficiently. Reduced Empty Miles: Minimize trips with underutilized capacity to cut emissions. 2-Dynamic Route Planning Real-Time Adaptation: AI-based routing considers traffic, weather, and road conditions. Energy-Efficient Paths: Prioritizes low-carbon routes to reduce fuel consumption. 3-End-to-End Visibility Real-Time Monitoring: Provides live tracking of shipments for all stakeholders. Predictive Insights: AI forecasts delays or disruptions and suggests alternatives. 4-Data Integration and Analytics Unified Platform: Aggregates data from carriers, warehouses, and shippers for holistic decision-making. Actionable Insights: Delivers AI-driven recommendations to enhance operational efficiency. 5-Carbon Footprint Reduction Emission Tracking: Quantifies and monitors CO₂ emissions for every shipment. Sustainability Reporting: Helps businesses comply with EU decarbonization policies and ESG goals. 6-Cost Optimization Lower Fuel Costs: Efficient routes and load planning reduce fuel expenditure. Scalable Model: Adaptive AI solutions grow with business needs, ensuring long-term ROI.

Keywords / Tags

Logistics-Artificial Intelligence

Keywords / Tags

Team Members

Bio

Skills

Intrests

Similar Ideas

14 July 2025

14 July 2025